PETROCHEMICAL INDUSTRY

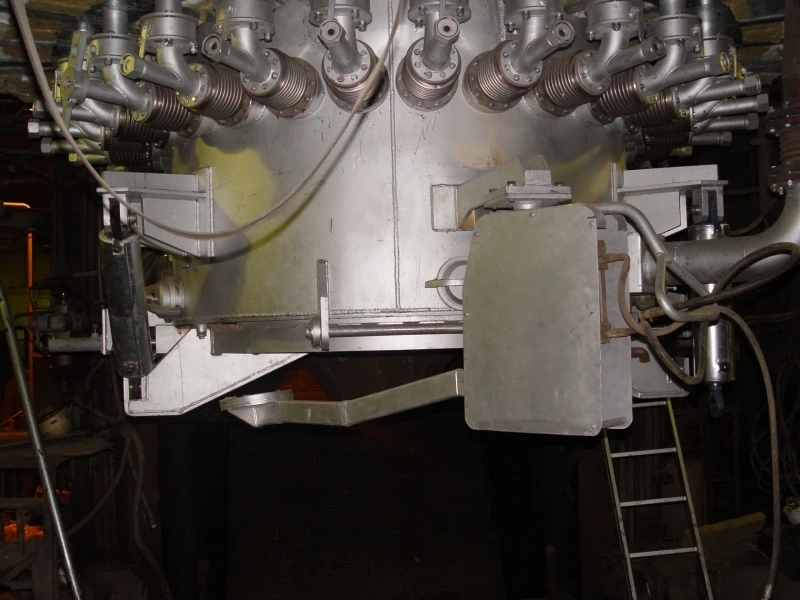

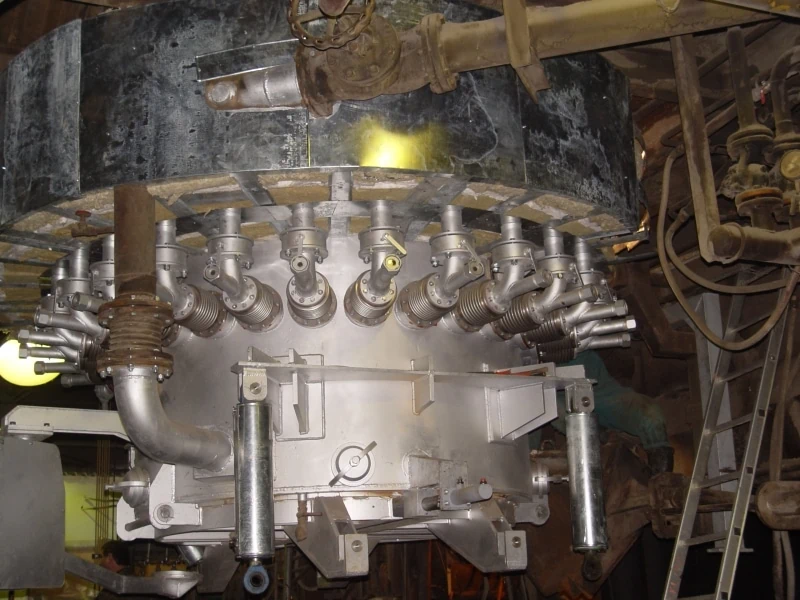

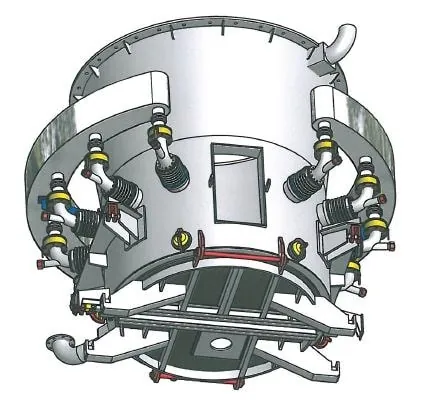

Reconstruction of furnaces

Charakteristic:

The Cupola oven remains very economical melting apparatus meeting the individual requirements for quality castings, efficiency of melting and temperature of iron. The most common type is a cupola oven with a stream of hot air with or without subsequent thermal incineration. The exhaust gas can be flow off by vacuum system placed above feeding door.

Columns

Charakteristic:

The Columns are operated under reduced pressure. By lowering of pressure is reducing boiling point of compounds in the masut, so there is possible at 360 -400 ° C to distill futher substances. The upper part of the column divertes steams of vacuum gas oil together with water vapor and pass them through exchanger. In the exchanger these gases change their heat with masut oil and go into condenser operated at 30-50 ° C and further condensate the gas oil and some portion of water.

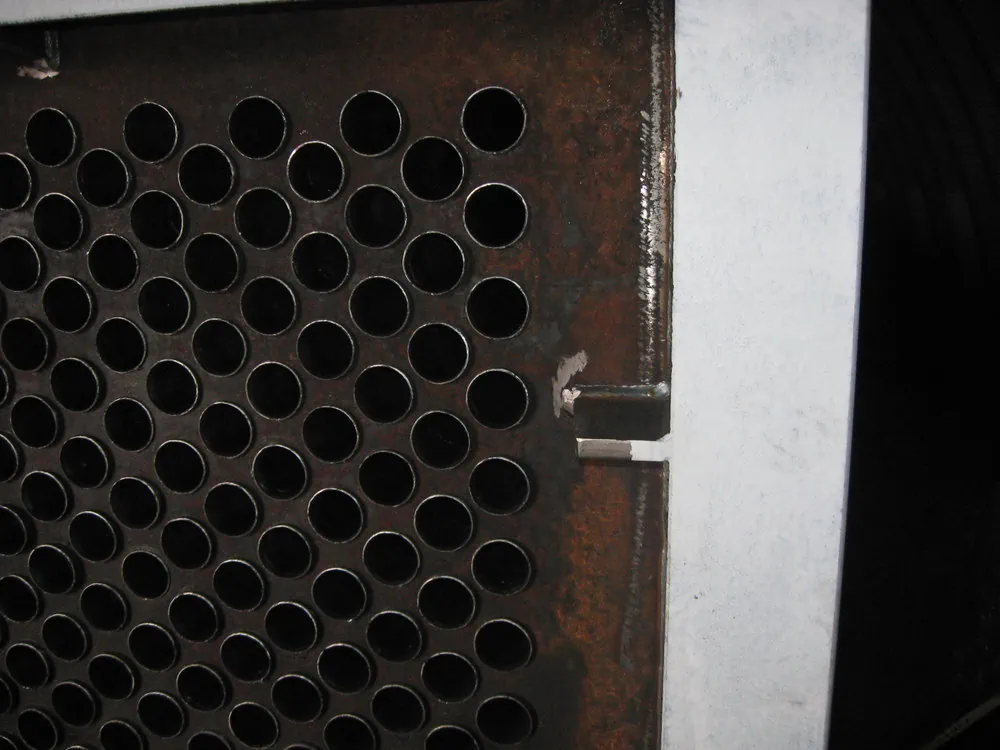

Heat Exchangers

Charakteristc:

The heat exchangers of classic design are provided with a cylindrical jacket and tube bundle , ribbed tubes and chambers . Arrangement of heat exchangers are based on the requirements of the project and the customer. Exchangers are manufactured as – standard condensers, heaters and the so on.

Applied materials:

Tubular bundle: stainless steel, carbon steel

Jackets: stainless steel, carbon steel

Nozzles: stainless steel, carbon steel

Flanges: stainless steel, carbon steel

Production and testing:

Manufactured in accordance with EN 12952 , EN 13445 , PED 97/23/EC and tested its own staff according to EN 473 and PED Level 2 supply exchangers according to ČSN, DIN , EN , AD Merkblatt/HP0 . Exchangers are manufactured according to the customer documentation .

Heaters

Charakteristc:

The snake and tube bundles are placed in combustion chambers and flues of energy facilities They are made of seamless pipes and metallurgical materials .

Applied materials:

Tubes : carbon steel, stainless steel

Production and testing:

The heaters are manufactured in accordance with current legislation reserved for pressure equipment and standing technical documentation according to STN , CSN , EN , AD Merkblatt/HP0 technical standard as well as ISO quality standard. They are manufactured in accordance with EN 12952 , 2000 AD Merkblatt HP0 PED 97/23/EC and tested by own personal staff according to EN 473 and PED Level 2 standars.

Non-pressure and pressure vessels

Non-heated pressure and non-pressure vessels vertical, horizontal, tanks

The stable pressure vessels for industrial use with accessories in accordance with regulation PED (Pressure Equipment Directive 97/23/EC ) and STN EN 13445 standard. The non-pressure tanks , storage silos and the like are used for the storage of materials and liquid substances in industrial applications ..

Applied materials:

carbon steel, stainless steel

Production and testing:

Manufactured in accordance with EN 13445 , PED 97/23/EC standrdand tested by own personal staff according to EN 473 and PED Level 2

Steel structures

Charakteristic

The steel structures are made of steel rolled profiles. They are manufactured welded and bolted. We produce them as well as fitted platforms, stairways and ladders. Depending on the type of application they are painted or zinc-coated for possibly aggressive environment.

Applied materials

Support columns: carbon steel

Reinforcement: carbon steel

Platforms and stairs: carbon steel

Accessories: zinc-coated gratings

Production and testing

The steel structures are manufactured in accordance with relevant specifications and valid certificates which are in compliance with the ISO procedures. Manufactering process is perfomed comfortably with STN EN technical standards and tested by own personal staff according to STN EN 473 and PED Level 2.