ENERGETICS industry

Complete boiler modules

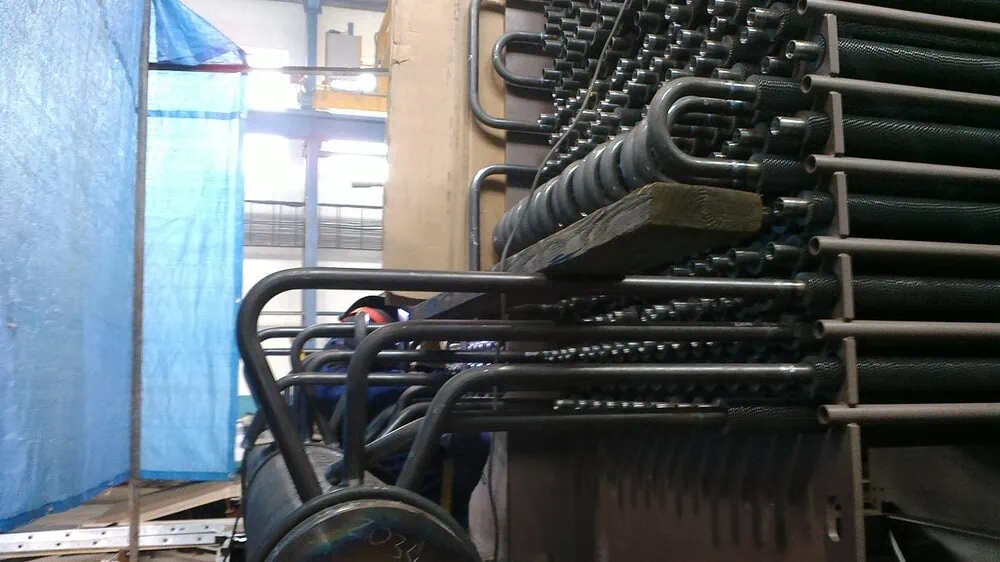

Heat exchange surfaces of power equipment /boilers/. Manufactured from seamless tubes in modular design

Boiler parts

/ moduls, economisers, chambers, suspensions, /

Heat exchange surface of energy installations / boilers are made of seamless pipes in a modular format. The individual modules in the channel design we set up the complete boiler for waste heat with well tried technical documentation.

Applied materials

rames, tabular heating elements / tube bundles, suspensions: carbon steel, stainless steel

Tubes, chambers: carbon steel alloy, non alloy, stainless steel

Isolations, fire-proof – technical materials,

Production and testing

The boiler modules are manufactured in accordance with relevant technical standards / STN EN 12952, 2000 AD Merkblatt HP0 and respective ISO standard. They are tested by own personal staff according to STN EN 473 and PED Level 2 standards.

Exhaust pipes and suspensions

Serve to extract the media from safety valves of technology into the atmosphere. They ensure a reduction of sound level in accordance applicable legislation.

Applied materials:

Carbon steel, stainless steel

Production and testing

Manufactured in accordance with EN 12952, PED 97/23/EC and tested by own personal staff according to EN 473 and PED Level 2 standards.

Combustors

The combustors serve as a heat source for locally heating of biomass incineration. They are delivered with all complte accessories in the model lines 500 ÷ 10000 with output from 0.5 MW to 30 MW . The products are manufactured in accordance with DIN, EN and with ISO quality standards. They are manufactured in accordance with EN 12952 , 2000 AD Merkblatt HP0 PED 97/23/EC and tested by own personal staff according to EN 473 and PED Level 2 .

Applied materials:

Frame: carbon steel, stainless steel

Jacket: insulated panels

Internal structures: carbon steel

Accessories: manways, flanges

Production and testing

The Products are manufactured in accordance with STN , EN and ISO quality standards . Manufactured in accordance with STN EN 12952 , Merkblatt 2000 HP0, PED 97/23/EC and tested by own personal staff according to EN 473 and PED Level 2

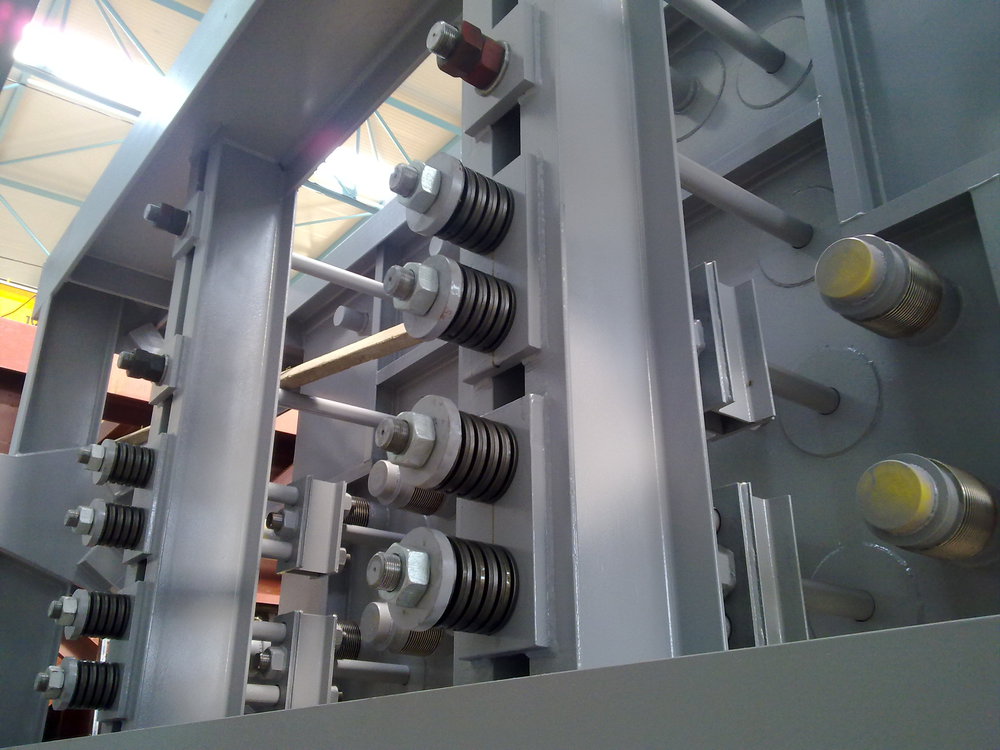

Flap valves

The regulation and shut-off flap valves are designed for continuous regulation or potential closing up of volumetric air flow, flue gases and other gaseous media. The flap valves are designed as leak free. The flap valves may be according to the method of use in single or multi-flap version with manual control or drive control version. The flap valves are designed so that they can work in various temperature intervals. Depending on the required temperature specification are used suitable materials for.

Flap valve consist of:

body made out of square or circular frame

inner flaps with shafts placed in the frame

mounting and a control unit of shaft with flaps

Production and testing

The flap valves are manufactured in accordance with EN 1090-2 and tested by own staff personal according to EN 473 and PED Level 2 standards.

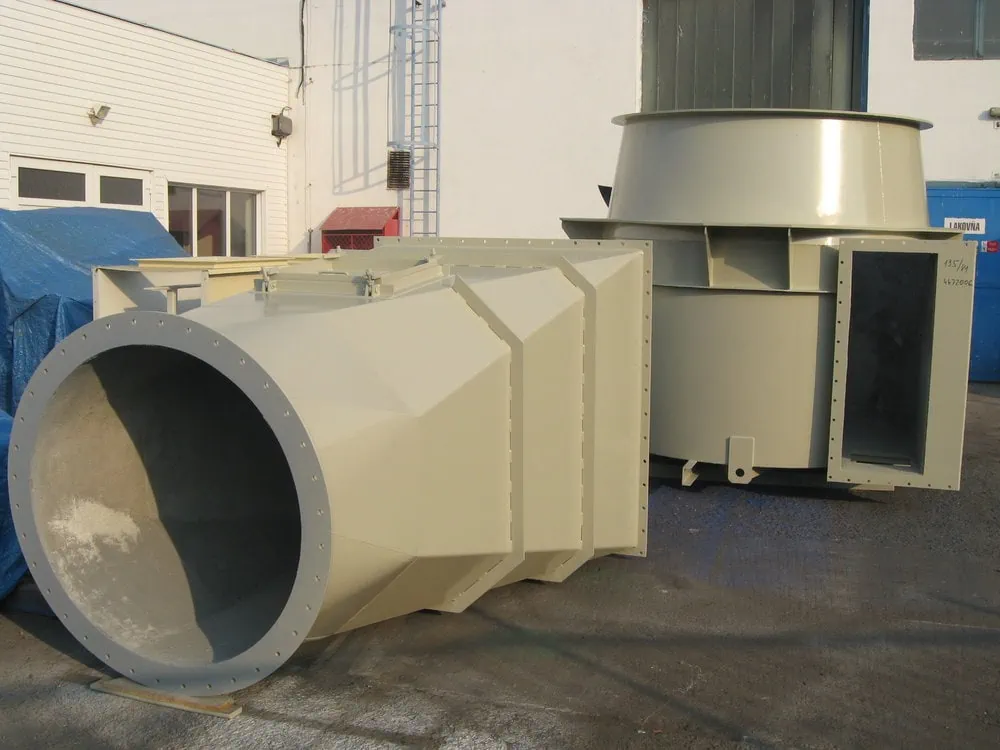

Flue ducts

Charakteristic

The flue ducts are made of alloy and non-alloy steel in circular and rectangular formats , depending on the type of application with inner or outer insulation.

Applied materials:

Walls: carbon steel, stainless steel

Reinforcement: carbon steel

Isolation: fire-proof materials

Accessories: manways, flanges

Production and testing

The flue ducts are manufactured in accordance with relevant specifications and valid certificates which are in compliance with the ISO standards. Manufactering process is perfomed comformably with EN 1090-2 standard and tested by own qualified staff personal according to STN EN 473 and PED Level 2

Spiral heat exchangers

Charakteristic

The spiral heat exchangers are used for recovery of waste heat from biomass source . Their layout are based on project and customer requirements.

Applied materials:

Body: carbon steel, stainless steel

Nozzles: carbon steel, stainless steel

Flanges : carbon steel, stainless steel

Using references:

Manufactured in accordance with EN 12952 , PED 97/23/EC and tested by own personal staff according to EN 473 and PED Level 2. We supply heat exchangers according to ČSN, DIN , EN , AD Merkblatt/HP0 technical standards. The exchangers are also manufactured according to the customer documentationaj podľa dokumentácie objednávateľa.

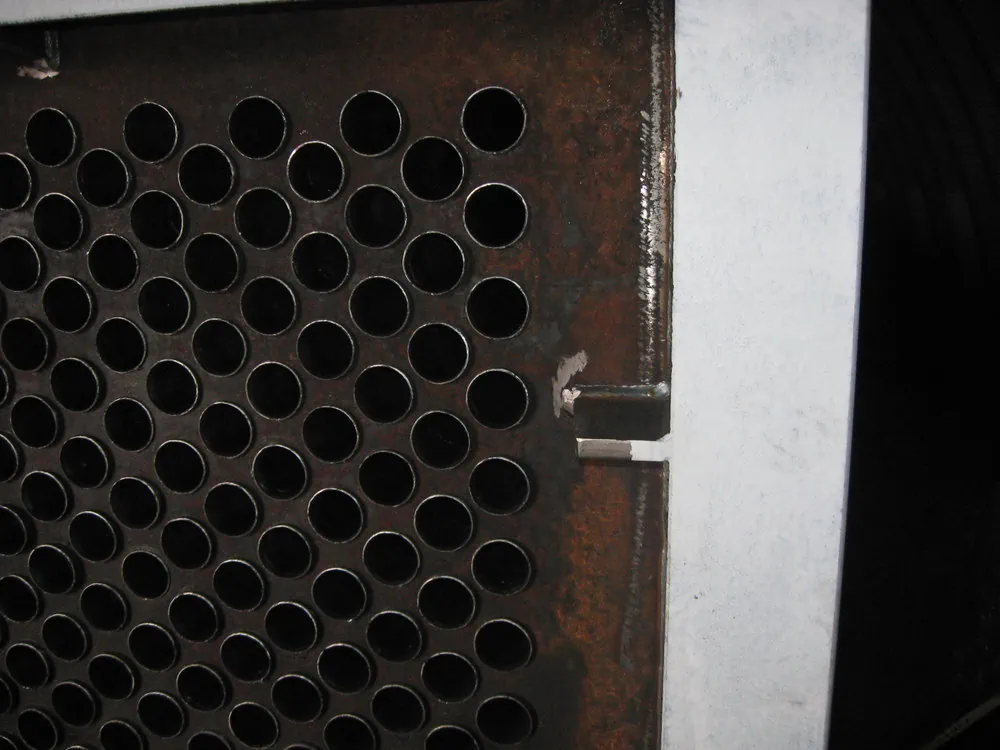

Heat Exchangers

Charakteristc:

The heat exchangers of classic design are provided with a cylindrical jacket and tube bundle , ribbed tubes and chambers . Arrangement of heat exchangers are based on the requirements of the project and the customer. Exchangers are manufactured as – standard condensers, heaters and the so on

Applied materials:

Tubular bundle: stainless steel, carbon steel

Jackets: stainless steel, carbon steel

Nozzles: stainless steel, carbon steel

Flanges: stainless steel, carbon steel

Production and testing:

Manufactured in accordance with EN 12952 , EN 13445 , PED 97/23/EC and tested its own staff according to EN 473 and PED Level 2 supply exchangers according to ČSN, DIN , EN , AD Merkblatt/HP0 . Exchangers are manufactured according to the customer documentation .

Heaters

Charakteristic:

The snake and tube bundles are placed in combustion chambers and flues of energy facilities They are made of seamless pipes and metallurgical materials .

Applied materials:

Tubes : carbon steel, stainless steel

Production and testing:

The heaters are manufactured in accordance with current legislation reserved for pressure equipment and standing technical documentation according to STN , CSN , EN , AD Merkblatt/HP0 technical standard as well as ISO quality standard. They are manufactured in accordance with EN 12952 , 2000 AD Merkblatt HP0 PED 97/23/EC and tested by own personal staff according to EN 473 and PED Level 2 standars

Pressure Pipes

Charakteristic:

The pressure pipes serve for transport of steam , water and other energy mediums in industrial applications . They are made of alloyed and unalloyed steels.

• Knees

• Bends

• placing elements for deposit and suspensions

Applied materials:

Pipe: carbon steel, stainless steel

Accessories: Carbon Steel

Production and testing:

Produced in accordance with relevant standards and valid certificates in accordance with the guidelines according to ISO standard. Manufactured in accordance with EN 13480 and tested by own personal staff according to EN 473 and PED Level 2.

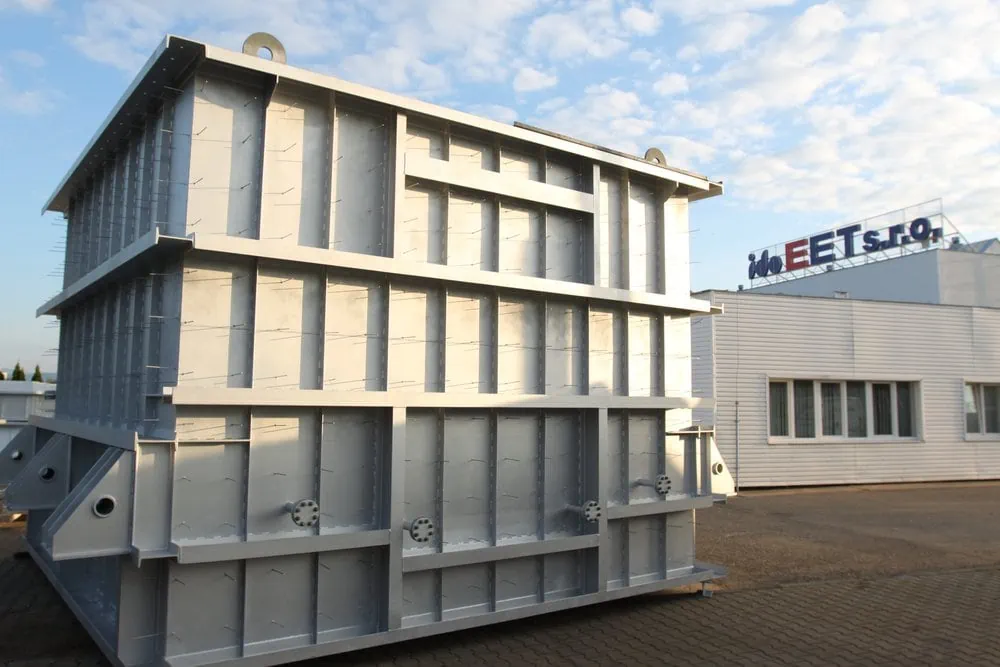

Non-pressure and pressure vessels

Non-heated pressure and non-pressure vessels vertical, horizontal, tanks

The stable pressure vessels for industrial use with accessories in accordance with regulation PED (Pressure Equipment Directive 97/23/EC ) and STN EN 13445 standard. The non-pressure tanks , storage silos and the like are used for the storage of materials and liquid substances in industrial applications .

skladovanie materiálov a tekutých látok v priemyselných prevádzkach.

Applied materials:

carbon steel, stainless steel

roduction and testing

Manufactured in accordance with EN 13445 , PED 97/23/EC standrdand tested by own personal staff according to EN 473 and PED Level 2.

Channels and non-pressure pipes

Characteristic

The Channels and non-pressure pipes are made of alloy and non-alloy steel in circular and rectangular formats. Depending on the mode of application may be fitted with an outer insulation.

Applied materials

Walls: carbon steel, stainless steel

Reinforcement: carbon steel

Isolation: fire-proof materials

Accessories: manways, flanges

Production and testing:

The products are manufactured in compliance with relevant standards, certificates as well as concerned ISO procedures. Manifactured products are conformed to STN EN 1090-2 and tested by own personal staff according to STN EN 473 and PED Level 2.

Steel structures

Charakteristic

The steel structures are made of steel rolled profiles. They are manufactured welded and bolted. We produce them as well as fitted platforms, stairways and ladders. Depending on the type of application they are painted or zinc-coated for possibly aggressive environment.

Applied materials

Support columns: carbon steel

Reinforcement: carbon steel

Platforms and stairs: carbon steel

Accessories: zinc-coated gratings

Production and testing

The steel structures are manufactured in accordance with relevant specifications and valid certificates which are in compliance with the ISO procedures. Manufactering process is perfomed comfortably with STN EN technical standards and tested by own personal staff according to STN EN 473 and PED Level 2

Chimneys

Charakteristic

The chimneys are made of steel rolled profiles which are manufactured as bending metal sheets. Beyond these articles we produce also various types of platforms, stairways and ladders. Depending on the type of application they are coated with paint and in the case possible aggressive environment zinc- coated

Applied materials

Body: carbon steel

Reinforcement: carbon steel

Platforms and stairs: carbon steel,

Accessories: grate bars – zink coated

Production and testing:

Manufactured in accordance with relevant standards and valid certificates in accordance with the guidelines according to ISO standard. Manufactured in accordance with STN EN technical statndards and tested by own personal staff according to EN 473 and PED Level 2